COR Pump System

- COR >

- COR Pump System

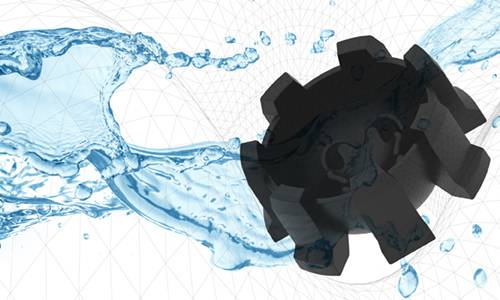

COR pump technology

The COR pump is a new pump technology in group of positive displacement pumps. Basic pumping idea came from the axial piston pump family.

The COR technology consist of 2 pumping principles: DoppelRotor (COR-DRP) and Tumbling multi chamber (COR-TMC). The COR pump system consists of 4 pieces of which 2 are rotating. No valves are needed. Most of the torque is converted into useful work as only one of the two rotating pieces is driven. Due to the design concept, the second one only needs torque to overcome its friction. The fluid is transferred through the center of the pump and transferred with the help of moving cavities and centrifugal force to the outlet on the periphery.

COR pump technology in positive displacement machines

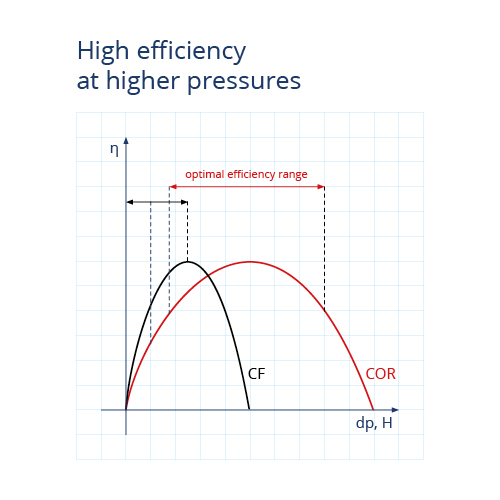

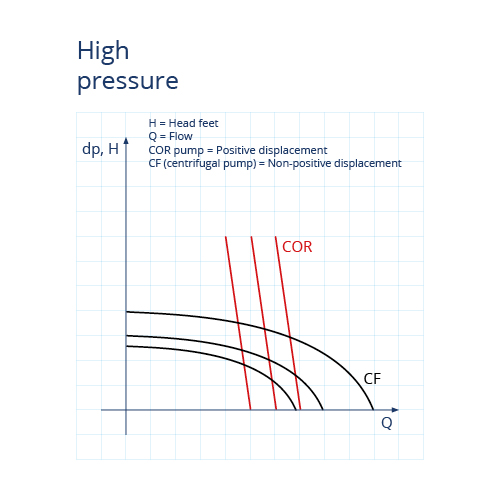

Pumps generally divided into hydrostatic and hydrodynamic. Hydro dynamical pumps operate on a hydrodynamic physical process in which there are pressure and energy changes in the proportional square of the speed of the rotor. Hydrostatic pumps (also known as positive displacement pumps) increase and decrease volume of the pump chamber during operating cycle.

Target properties of hydrostatic pumps

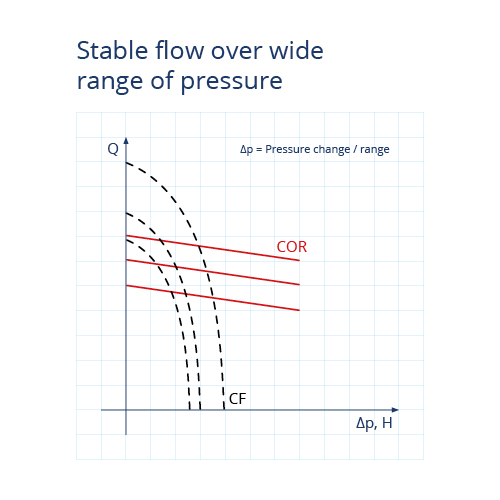

- Stable efficiency in wide working area (over different flow or pressure) with low noise emissions

- High reliability at high mechanical and/or thermal loads

- Small size and weight, low price, easy assembly and servicing

- Possibility of integration with control devices (pressure, flow, temperature sensors)

- Possibility of operating over wide viscosity range of liquids

- Low pulsation of pressure and flow.

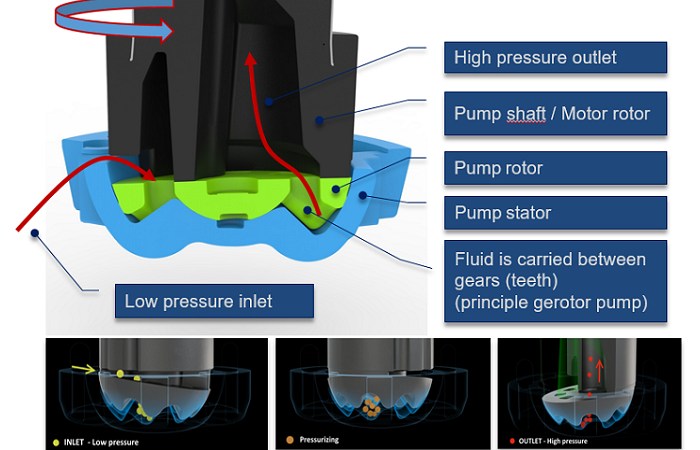

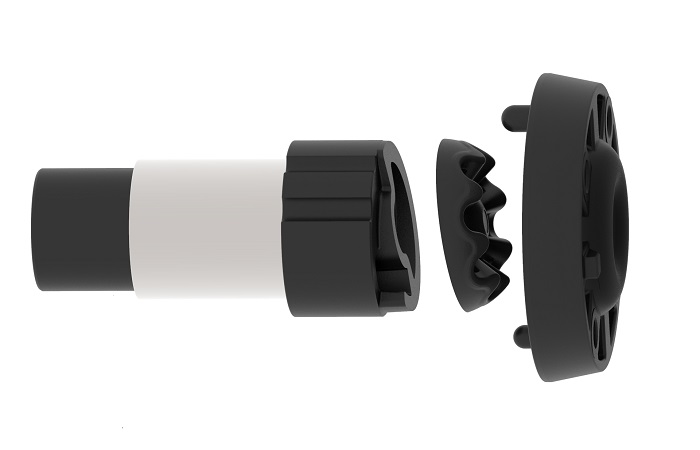

Main pump components

The COR pump consists of a

- pump stator with a 3D inner gear shape with n teeth and

- a pump rotor with n+1 teeth, which fits on the stator shape under a certain angle.

The gear shape (teeth) is arranged axially and the shape of the teeth enables simultaneous engagement, which ensures sealing between individual interdependent gaps.

Engagement of fluid

The pump design is based on 3-dimensional trochoid gear shape with function of pulsating chambers for volume displacement. The operating principle is based on the formation of the separate chambers, closed by two gearing topographies. When rotated, the chambers open (grow) and close (shrink) simultaneously and control fluid displacement precisely. Connection of the pulsating chambers with suitable control openings (with matching contours) results in the displacement effect. One of basic outputs of this pump design is pressure separation effect. The enveloping part (pump housing) also serves as a separating element between the pressure side and the suction side.

COR-DRP is analogous to a ge-rotor pump, as the fluid between the teeth is displaced by different rotational speeds of the rotors. COR-TMC is analogous to an axial piston pump, as the fluid is displaced by opening and closing of chambers.